Building A Better Trigger: The Man In Charge At Timney Triggers

Sep 1st 2023

Recoil Magazine features Timney Triggers' owner, John Vehr. Click here to read the original article.

Eccentric is a word that’s sometimes interpreted in a negative sense — wacky, disjointed, or impractical. But the true definition of the word simply implies unconventionality or divergence from established norms. When this type of atypicality is harnessed, it yields innovation.

Case in point, Timney Triggers owner John Vehr isn’t the kind of person you imagine when you think of a gun industry executive.

His long hair, wry smile, and laid-back demeanor seem more appropriate for a Hawaiian beach than a corporate boardroom. When we arrived at his home, built on a remote 27-acre property surrounded by Arizona’s Coconino National Forest, he greeted us barefoot and welcomed us into a living room that contains a second-story ball pit loft.

Then, he asked if we wanted to try on his bison robe. Already sweating in the August heat, we politely declined. John proceeded to give us a tour of his yoga room, vegetable garden, and emergency bunker that was equipped with a vault door, remote-controlled security shutters, and a hidden escape hatch.

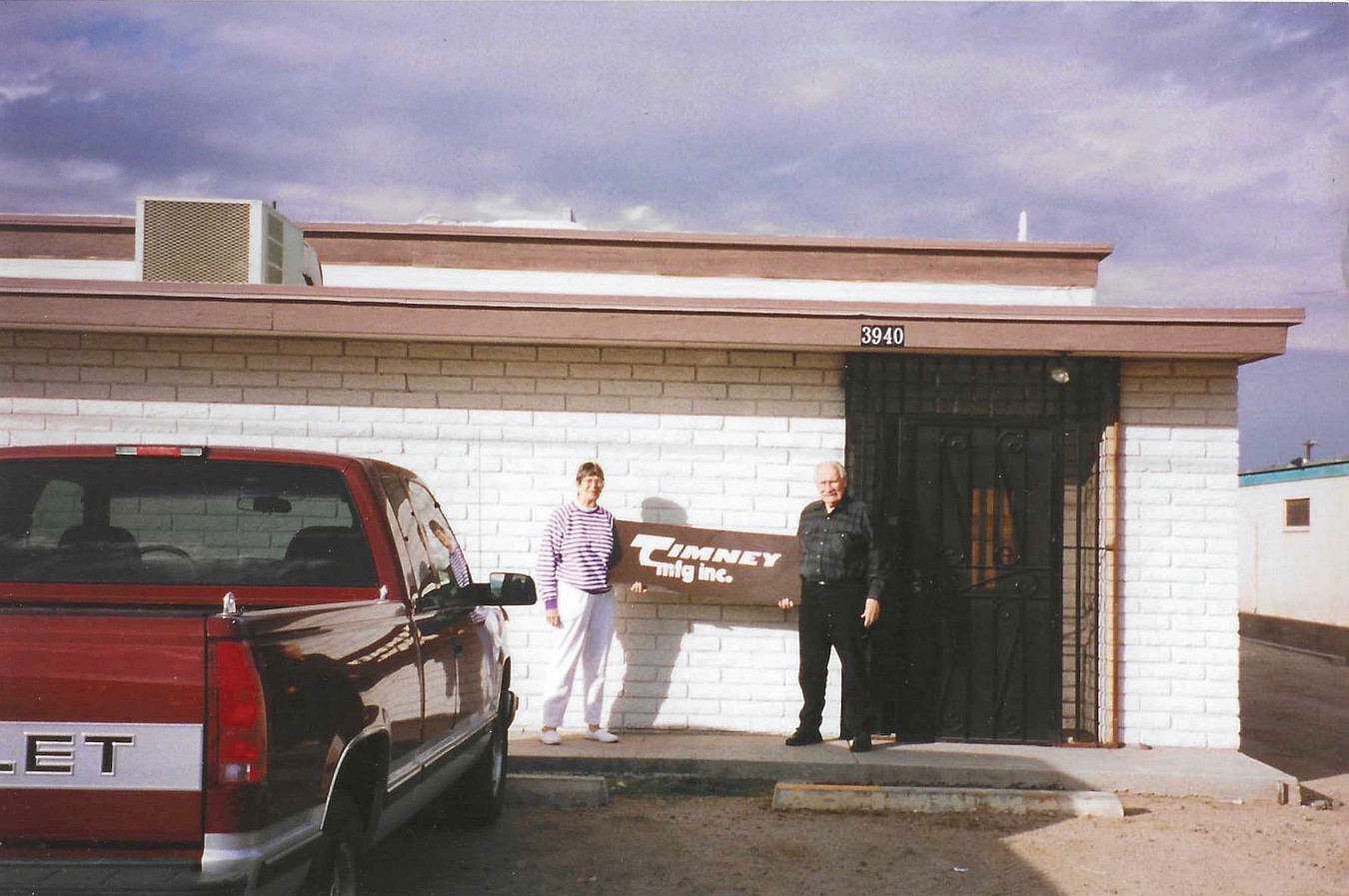

John’s unabashed eccentricity has helped him carve out a unique path to success for his family owned business. More than 40 years ago, his parents scraped together the funds to buy Timney, a company that was on the brink of collapse after a warehouse fire destroyed nearly all its inventory.

Since then, the Vehr family rebuilt and reinvented this modular trigger company, and John brought it into the 21st century with modern machines that streamlined manufacturing. We sat down to talk with John about helping his parents in the Timney workshop, taking the reins of the company, and maintaining a culture that truly puts the customer first.

RECOIL: Timney’s history dates back all the way to 1946. Tell us a little about the post-World War II era of the company, and how it eventually came to be owned by your parents, Paul and Rosemary.

John Vehr: In 1946, Allen started the company because he had an idea for a modular trigger, and as a gunsmith with an incredible engineering mind, he was able to create it.

During Allen’s time with the company, it went through fits and spurts of profitability. In the late ’70s, Allen actually ended up moving the company from Downey, California, over to Phoenix, Arizona, because one of his business partners was out here. His partner was able to keep the company going while Allen focused on doing what he loved: making triggers.

Unfortunately, in 1980, there was a big fire at the shop that destroyed nearly everything. Unable to rebuild the company, Allen was forced to sell Timney Triggers. Thankfully, my folks, Paul and Rosemary, were looking to buy a company at the time because they had taken a look at their retirement funds and realized they needed a plan B. My dad had heard of Timney before and liked their products, so they decided to buy the company. What’s the worst that could happen, right?

They took out a second mortgage on the house and used the money to purchase Timney Triggers. For the first two or three years they lost a lot of money, but they were hardworking people who were determined to turn the company around. And they did. They were able to take a company that was on the brink of bankruptcy (multiple times) and build the foundation that Timney Triggers stands on today.

In your opinion, what was the cornerstone of your parents’ success in this industry?

JV: Putting the customer first. When my folks bought Timney, that was something that my mom would say over and over again. Customer service is everything. Without good customer service you’re just another company. But Timney Triggers isn’t just a company. Everything that we do, from our rigorous trigger testing, to marketing, to packaging and shipping, is all for our customers.

How did you begin working at Timney? What were your first job responsibilities?

JV: I was hired as the marketing manager in 1994. Since it was a tiny company at the time, I did marketing for about five hours a week, and the rest of the time I unloaded and loaded manual milling machines, assembled and tested triggers, and worked in customer service. I spent the majority of my time learning about the shop and only a fraction of the time doing marketing. This helped me get to know the inner workings of the company and what it takes to make a trigger. They are skills that I took with me as I built upon the foundation my parents had created.

The passing of a parent is always a difficult time, much less losing both parents only a few weeks apart. On top of it all, you had a family business to run. How did you keep up momentum during this tumultuous period?

JV: I buried myself in my work. I had two young kids, a wife, and a business I had just purchased, so when I wasn’t being a dad and a husband, I poured myself into my work. It was the best way I could grieve them. Maintaining the business and making it something they would be proud of was my way of honoring their memory.

During this time, I reached out to some friends to have a tribute made and put into a few magazines. They were able to put something into two or three magazines, which made me happy. To my parents, their greatest legacy was their kids, but to the world, their legacy was Timney Triggers. Having their memory honored in that way brought me so much peace.

What were the greatest challenges you faced as you took the reins of the company?

JV: Bringing manufacturing into the modern age and upgrading the caliber of people at Timney. Timney had a bunch of relics we called “machines,” which we used to make the trigger parts. But the machines were only able to get close to the correct specs — we then had to use surface grinders and lapping machines to get the parts into tolerances. If we were to continue to make parts that way, Timney would not have survived much longer.

So, I did something crazy and bought a wire-EDM with all the money I had left. I didn’t know how to use the thing, so I talked to someone who did: Calvin Motley. After he and I had a few conversations, I recognized some hidden talent in Calvin that he didn’t even know about. Together, we were able to create the overarching principles of production that we still use to this day.

You’ve made it clear that you truly value the people who make up Timney, going so far as to name parts after employees who developed them. At the same time, you’ve strongly emphasized automation and high-tech manufacturing. How do man (or woman) and machine work together to build a better trigger?

JV: Great question. It is my belief that machines are best for carving parts and moving them around. However, humans are not machines. They do not work best by mundanely moving parts around; they work best while being creative.

So many businesses see people as machines and work them accordingly, but this is such a misuse of the raw talent human beings have. We have learned that when we encourage people to be creative with their ideas, they create incredible things.

This is how we are able to do what we do. We set up machines to run parts, without people touching them, and we give people the space to let their creativity flow. In return, we get pure magic.

A few thousandths of an inch can make the difference between a great trigger and one that’s barely functional. What quality control systems do you use to ensure every part works as intended?

JV: When the company was smaller, we maintained quality through a culture of quality — meaning nothing was necessarily taught, it was just ingrained in the minds of the people at the shop.

As the company grew, we realized we had to institute quality policies in order to maintain that culture of quality. So, we hired Lisa Ann Forbes to be the director of quality management systems. Since her start at Timney, Lisa has produced an even more robust quality system through creating new processes and policies. With the help of Lisa’s genius, we have been able to clear the path to excellence, allowing us to see Timney’s bright future.

The Timney lineup has expanded to more than 170 models, ranging from triggers for precision bolt guns to everyday carry pistols. What does the development process for a new trigger look like?

JV: It used to be just Calvin and me sitting down, talking about what trigger we wanted. We would come to a conclusion, Calvin would go make it, and then we would test it to make sure it worked.

However, Timney has grown quite a bit since then, so now we have something called the New Product Development Packet. It’s an extensive document that outlines the nitty-gritty process new triggers have to go through before they can make it into customer hands.

From engineering to production to marketing to finance, everything is laid out so each trigger goes through the same process. It’s how we can ensure we are making the World’s Finest Trigger.

Has any weapon platform been especially difficult to get just right?

JV: The Tavor. We have a new one in the works, and we are still working to refine it so we can have it just right. Precision is key.

Let’s address the long-standing debate — are anti-walk and/or anti-rotation pins necessary for AR drop-in triggers? How can users ensure trigger pin walk doesn’t become an issue?

JV: The simple answer: no, not in our triggers. In our modular AR triggers, we have lock screws that mechanically bind the pins to the receiver.

You can use whatever pins you want; as long as you tighten those lock screws our trigger will not move. As I have said before, we have some of the brightest minds working at Timney, and those bright minds come up with the most innovative ideas.

What does the future hold for Timney? Is there a specific project that’s on your personal “bucket list?”

JV: My personal bucket list for Timney is making sure that the culture we’ve created continues to thrive as we accelerate our growth. To me, the culture that Timney maintains is what separates us from other companies in this industry. Our goal as a company is to make products that blow people’s minds, and with the help of the foundation of our culture, we have been able to do that for over 75 years.

JOHN VEHR

Age: 60

Hometown: Phoenix, AZ

Job Title: El Presidente of Timney Triggers

Family: Wife (Jody) and two children (Andres and Talia)

Pets: Two Neapolitan mastiffs (Maisie and Riley)

Role Models:

- My mom, Rosemary Vehr. She has a natural business mind, and watching/learning from her helped me realize that I have a natural business mind myself.

- The people I work with at Timney. I learn new things from them all the time.

- Steve Hardison. He was a coach of mine during a pivotal time in my life. Through him I was able to learn different ways to lead and inspire people.

Recommended Reading List:

- Greenlights by Matthew McConaughey

- Big Magic by Elizabeth Gilbert

- Think and Grow Rich by Napoleon Hill – one of the greatest books I have ever read. It’s almost 100 years old, and the precepts are as true today as they were when it was written.

Favorite Quote(s):

“If one advances confidently in the direction of his dreams, and endeavors to live the life which he has imagined, he will meet with a success unexpected in common hours.” – Henry David Thoreau

“When it comes your time to die, be not like those whose hearts are filled with the fear of death, so that when their time comes, they weep and pray for a little more time to live their lives over again in a different way. Sing your death song and die like a hero going home.” – Tecumseh

Favorite Drink: It used to be red wine, but I suppose today it’s club soda.